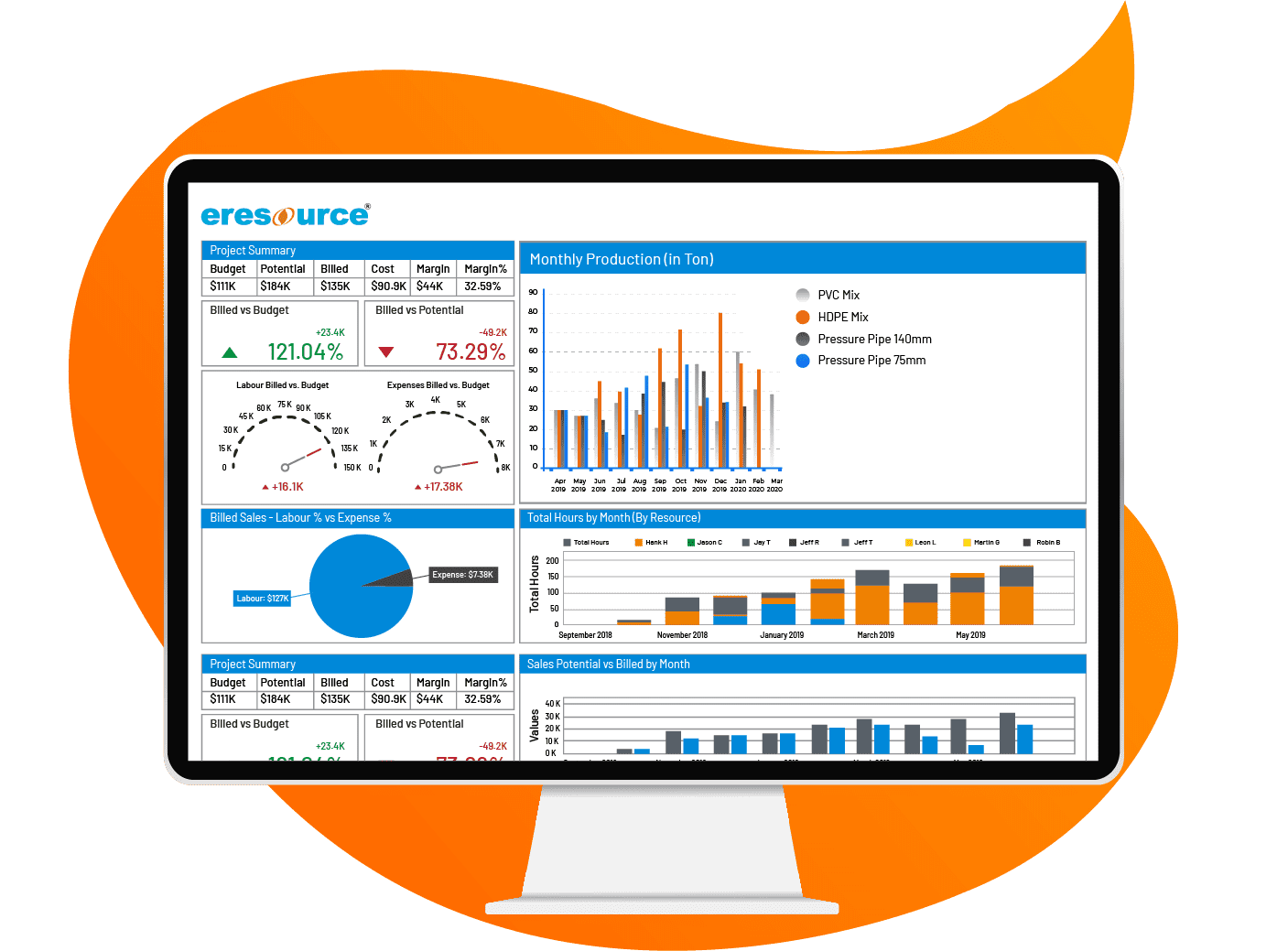

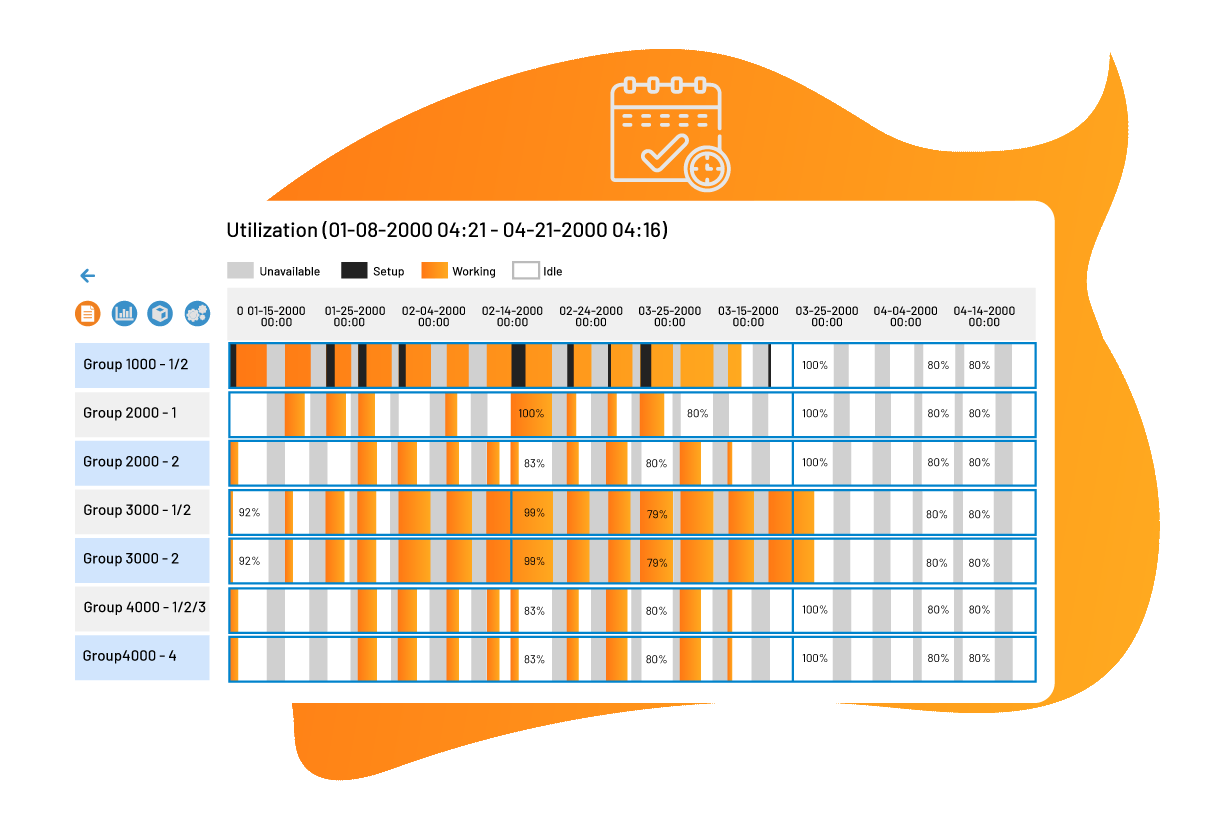

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.